Autonomous Driving System

LoopX Autonomous Driving System (ADS) integrates perception, mapping and localization, motion planning, and control software to enable your existing mining vehicles to operate autonomously. This shift significantly enhances both operational efficiency and safety within mining sites by relocating equipment operators from hazardous underground locations to secure aboveground operation centres.

Autonomous Driving System

The Problem

The underground mining sector faces severe challenges that demand innovative solutions. Safety is paramount, with mobile equipment interactions topping the list of risks in this hazardous environment.

Prolonged downtime during blasting operations and shift changes results in significant productivity losses. In mines operating with two nine-hour shifts, up to 6 hours of non-productive time daily severely impacts overall efficiency.

Labor shortages compound these issues. With over 50% of its existing workforce expected to retire by 2030, this impending shortage of skilled workers requires a transformative solution to maintain operational continuity.

Furthermore, traditional human-driven mining practices often involve suboptimal routes and equipment operation, resulting in unnecessary energy consumption and increased environmental impact.

LoopX Autonomous Driving System solves all these problems.

How It Works

Advantages

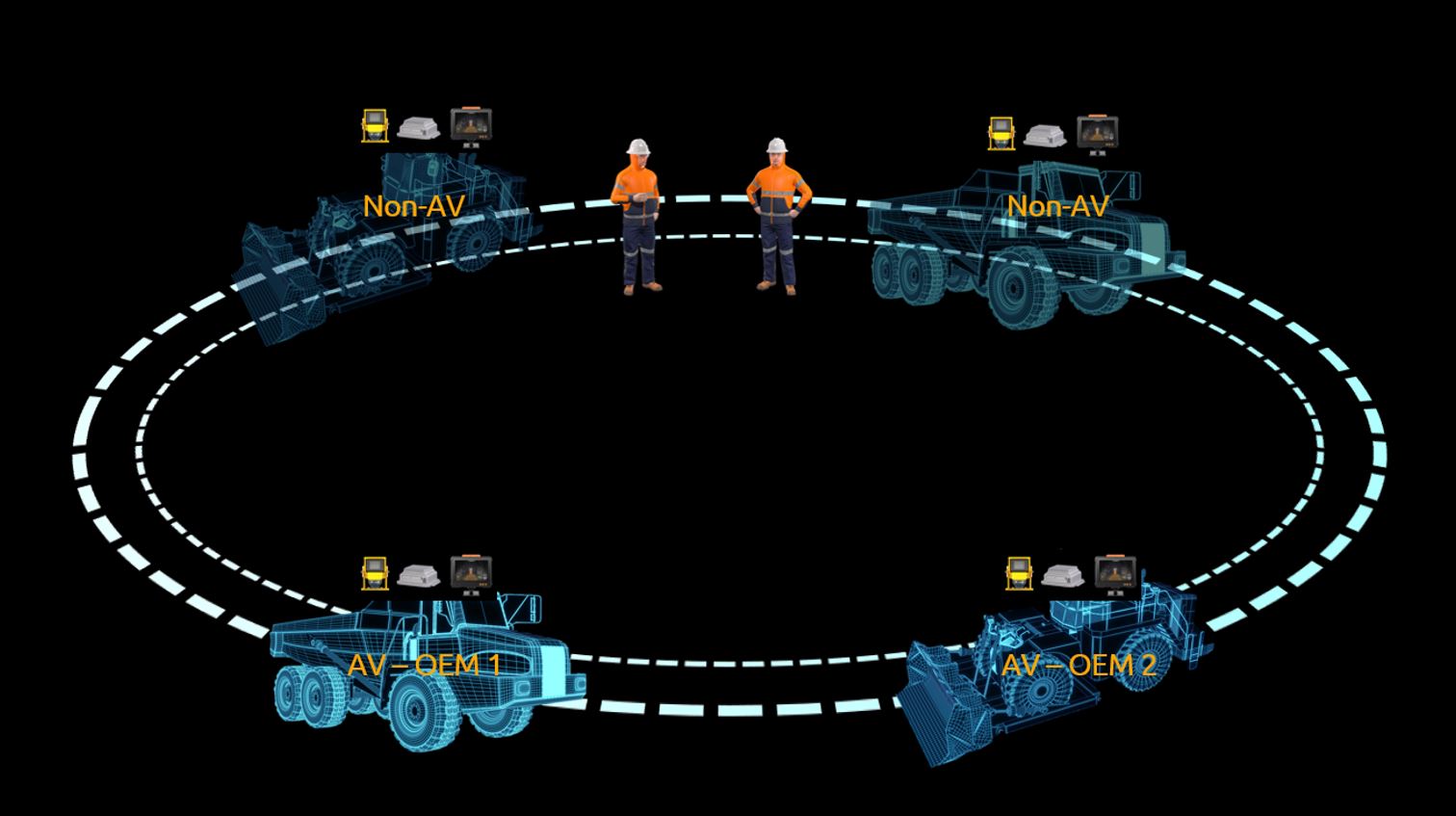

Fully Interoperable

It is designed to work seamlessly with a variety of equipment, making it interoperable with different OEMs and vehicle types. We understand that mining operations often involve a mix of machinery, and our flexibility ensures a smooth integration tailored to your mine’s specific needs.

Continuously Evolving Capabilities

It uniquely combines patented AI algorithms with an extensive mining dataset. Unlike many autonomous systems that lack AI, ours excels in adaptability and efficiency. This AI-driven approach equips your equipment with continuously evolving capabilities, ensuring they stay at the forefront of technological advancement and operational efficiency.

Specialization in Ancillary Machinery

Existing autonomous solutions from large OEMs focus on production machinery, such as haulage trucks. Our experience on ancillary machinery, such as light utility vehicles, addresses a unique niche in the market.

Benefits

Enhanced Safety

It removes the exposure of equipment operators to hazardous conditions, creating a significantly safer work environment for all stakeholders.

Boosted Productivity

It significantly enhances productivity by ensuring mining equipment remains operational during shift changes and blasting windows, reclaiming valuable hours previously lost, resulting in a 20% increase in productivity.

Reduced Fuel Consumption and Emissions

It effectively reduces greenhouse gas (GHG) emissions in mining operations by 15% through consistent driving behaviour and reduces operational costs by minimizing fuel waste, leading to a significant reduction in overall environmental impact.